Transportation by Nanotechnology evolution

Introduction

Nanotechnology is a rapidly evolving field that involves the manipulation of matter at the nanoscale, or the scale of atoms and molecules. One area where nanotechnology is having a significant impact is the transportation industry. The development and application of nanotechnology in transportation have the potential to revolutionize the way we travel, making it safer, more efficient, and more sustainable.

Nanotechnology is being used to develop advanced materials that are stronger, lighter, and more durable than traditional materials. These materials can be used in various transportation components, such as vehicle bodies, tires, and engines, to improve performance, reduce weight, and enhance fuel efficiency.

Nanotechnology is also being used to develop more efficient energy storage systems, such as high-capacity batteries and supercapacitors, which can extend the range of electric vehicles. In addition, nanoparticles can be used to create sensors and safety features in vehicles, such as anti-collision systems and smart airbags.

Furthermore, nanotechnology can be used to create smart coatings and windows that can adjust to changing weather conditions or detect and repair damage to a vehicle’s paint job. These coatings and windows can also improve fuel efficiency and reduce the need for maintenance.

However, there are also potential drawbacks to the use of nanotechnology in transportation, such as the potential toxicity of nanoparticles and unintended consequences. Therefore, it is important to carefully consider the potential risks and benefits of nanotechnology in transportation before implementing these technologies on a large scale.

Overall, the continued development and application of nanotechnology in transportation have the potential to revolutionize the industry, making it safer, more efficient, and more sustainable. As research and development in this field continue, we can expect to see even more innovative applications of nanotechnology in transportation in the future.

Here are some potential impacts of nanotechnology on transportation:

Lightweight materials

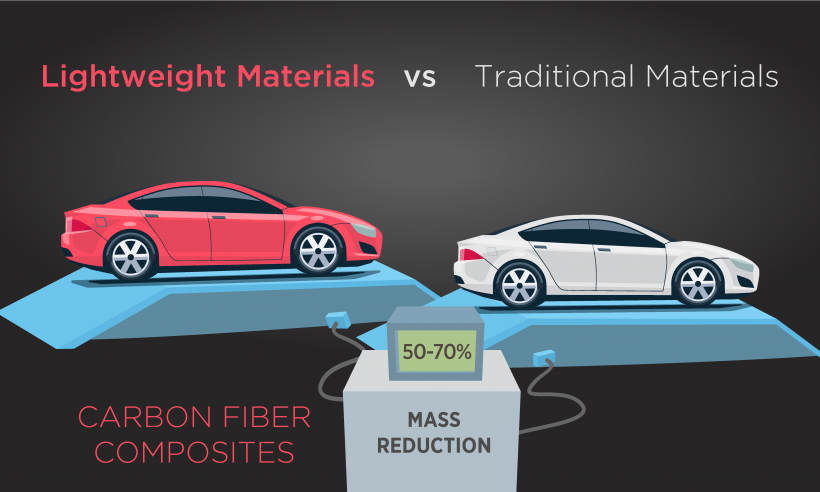

One of the most significant impacts of nanotechnology on transportation is the development of lightweight materials. Nanomaterials, such as carbon nanotubes and graphene, have unique mechanical, thermal, and electrical properties that make them ideal for creating lightweight materials for vehicles.

By incorporating nanomaterials into various components of vehicles, manufacturers can create materials that are stronger, more durable, and lighter than traditional materials. For example, nanomaterials can be used to create strong, lightweight composites for vehicle bodies, which can improve fuel efficiency and reduce emissions.

Nanomaterials can also be used to create lightweight components for engines, such as pistons and crankshafts, which can improve engine performance and reduce weight. In addition, nanomaterials can be used to create lightweight tires, which can reduce rolling resistance and improve fuel efficiency.

The use of lightweight materials in transportation has several benefits, including improved fuel efficiency, reduced emissions, and increased performance. For example, reducing the weight of a vehicle by 10% can improve fuel efficiency by up to 7%. This reduction in weight can also result in a decrease in emissions, as less fuel is burned to move the vehicle.

Furthermore, the use of lightweight materials can improve the performance of vehicles, such as faster acceleration and better handling. Lightweight materials can also lead to a longer lifespan for vehicles, as they are less prone to wear and tear.

Overall, the use of nanomaterials to create lightweight materials is a promising application of nanotechnology in transportation. As research and development in this area continue, we can expect to see even more innovative applications of nanomaterials in the development of lightweight vehicles.

Improved energy storage

Nanotechnology is also being used to develop improved energy storage systems for transportation, which is crucial for the development of electric vehicles. One of the main challenges facing electric vehicles is the limited range due to the limitations of current battery technology.

Nanotechnology is helping to address this challenge by developing advanced battery materials that can store more energy and provide a longer range for electric vehicles. Nanomaterials, such as lithium-ion nanowires, can be used to create higher-capacity batteries that can store more energy in a smaller space.

Nanotechnology is also being used to develop supercapacitors, which can store energy more efficiently than traditional batteries. Supercapacitors are capable of charging and discharging much faster than batteries, making them ideal for use in hybrid electric vehicles.

In addition, nanotechnology is being used to develop energy harvesting technologies, such as piezoelectric materials, which can convert mechanical energy from the vehicle’s movement into electrical energy. This energy can then be used to power various vehicle components, reducing the reliance on traditional energy storage systems.

Improved energy storage systems are essential for the widespread adoption of electric vehicles, and the application of nanotechnology is playing a crucial role in developing these systems. As research and development in this area continue, we can expect to see even more innovative applications of nanotechnology in energy storage for transportation.

Self-healing materials

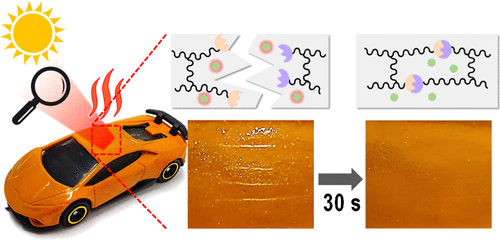

Self-healing materials are another promising application of nanotechnology in transportation. These materials have the ability to repair damage on their own, which can improve the durability and lifespan of various components in vehicles.

One example of self-healing materials is a polymer that incorporates small capsules of healing agents. When the polymer is damaged, the capsules break open, releasing the healing agents, which fill the cracks and restore the material to its original state.

Nanotechnology can also be used to create self-healing coatings for vehicles. These coatings can repair themselves when they are scratched or damaged, protecting the underlying material from further damage.

The use of self-healing materials in transportation has several benefits, including reduced maintenance costs, improved safety, and increased durability. By repairing damage on their own, vehicles can last longer and require less frequent repairs, saving time and money for vehicle owners.

Self-healing materials can also improve safety by reducing the risk of catastrophic failures in critical components, such as structural supports or engine components. In addition, the use of self-healing coatings can improve the aesthetics of vehicles by maintaining a smooth and unblemished appearance.

Overall, self-healing materials are a promising application of nanotechnology in transportation, and research and development in this area are ongoing. As more advanced self-healing materials are developed, we can expect to see even more innovative applications in the automotive industry, leading to safer, more durable, and more cost-effective vehicles.

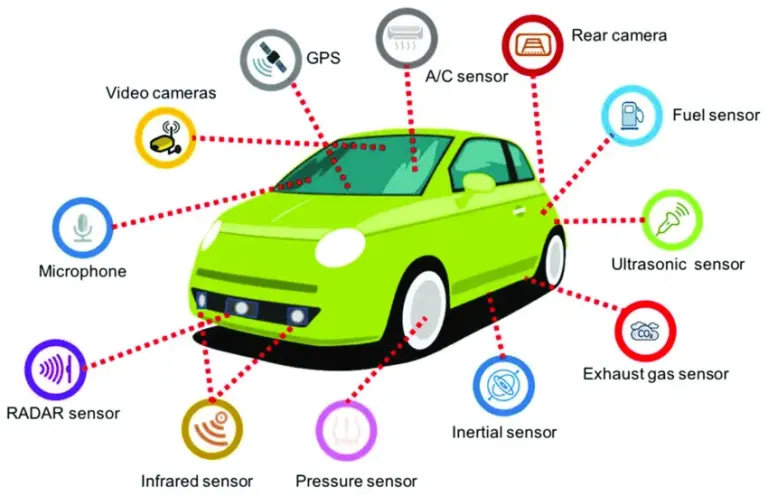

Improved sensors such as Nanosensors

Nanotechnology is also being used to develop improved sensors for transportation. Sensors play a crucial role in various aspects of transportation, including safety, efficiency, and environmental impact.

Nanomaterials, such as carbon nanotubes and graphene, have unique properties that make them ideal for creating advanced sensors for transportation. These materials can detect changes in temperature, pressure, and other factors with high sensitivity and accuracy.

Improved sensors can enhance safety in vehicles by detecting potential hazards and warning drivers of impending danger. For example, sensors can detect the presence of other vehicles, pedestrians, and obstacles, and alert drivers to take appropriate action.

Sensors can also improve the efficiency of vehicles by providing real-time information on fuel consumption, engine performance, and other factors. This information can be used to optimize vehicle operation and reduce fuel consumption, leading to lower emissions and cost savings for vehicle owners.

In addition, sensors can be used to monitor environmental factors, such as air quality and noise levels, which can inform policies and regulations aimed at reducing the environmental impact of transportation.

Overall, the use of nanotechnology to develop advanced sensors is a promising application in transportation, with potential benefits for safety, efficiency, and environmental impact. As research and development in this area continue, we can expect to see even more innovative applications of nanomaterials in the development of advanced sensors for transportation.

| Sensor Type | Function(s) |

|---|---|

| Temperature | Measures temperature or changes in temperature |

| Pressure | Measures pressure or changes in pressure |

| Proximity | Detects the presence or absence of nearby objects or materials |

| Motion | Detects movement or changes in motion |

| Light | Measures the intensity, color, or direction of light |

| Humidity | Measures the amount of moisture in the air or a substance |

| Gas | Detects the presence or absence of specific gases or changes in gas levels |

| Sound | Measures sound levels or changes in sound |

| pH | Measures the acidity or alkalinity of a substance |

| Accelerometer | Measures acceleration or changes in acceleration |

| Gyroscope | Measures rotation or changes in rotation |

| Magnetometer | Measures magnetic fields or changes in magnetic fields |

| Infrared | Detects infrared radiation or changes in infrared radiation levels |

| Ultrasonic | Uses sound waves to detect the distance to an object or changes in distance |

| Optical | Measures the intensity, color, or direction of light, often used in imaging |

| Biometric | Identifies and measures unique physiological or behavioral traits of an individual |

Note: This is not an exhaustive list of all sensor types and their functions, but rather a selection of some of the most commonly used sensors.

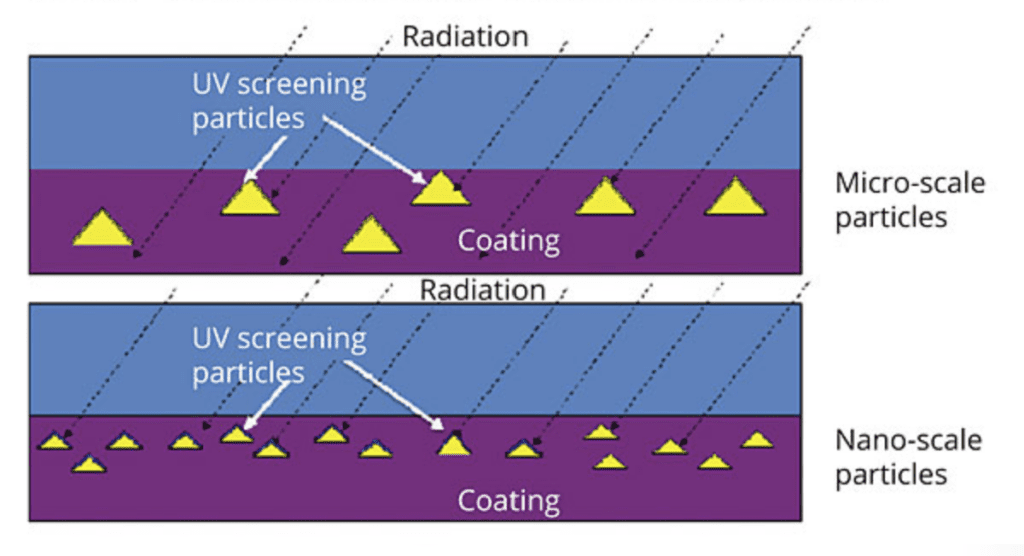

Smart coatings

Smart coatings are a type of nanotechnology application that can be used in transportation to improve the durability, safety, and environmental performance of vehicles. Smart coatings are materials that can change their properties in response to external stimuli, such as temperature, light, or pressure.

One example of a smart coating is a hydrophobic coating that repels water and other liquids, protecting the underlying material from corrosion and damage. Another example is a self-cleaning coating that can reduce the accumulation of dirt and grime, improving the appearance and reducing maintenance needs of vehicles.

Smart coatings can also be used to improve safety in transportation by providing additional functionality to vehicle components. For example, a smart coating on a windshield can enhance visibility by repelling water and reducing glare.

Smart coatings can also be used to reduce the environmental impact of transportation by improving the efficiency of vehicles. For example, a smart coating on the surface of a vehicle can reduce air resistance, improving fuel efficiency and reducing emissions.

The use of smart coatings in transportation is a promising area of research and development in nanotechnology, with potential benefits for durability, safety, and environmental performance. As more advanced smart coatings are developed and applied to various vehicle components, we can expect to see even more innovative applications in the automotive industry, leading to safer, more durable, and more sustainable vehicles.

Smart windows

Smart windows are another promising application of nanotechnology in transportation. Smart windows can change their properties in response to external stimuli, such as light, temperature, or electricity.

In vehicles, smart windows can improve comfort and safety by controlling the amount of light and heat that enters the vehicle. For example, smart windows can automatically adjust their tint to reduce glare and heat in sunny conditions, providing a more comfortable ride for passengers.

Smart windows can also improve safety by reducing the risk of distracted driving. For example, smart windows can display information, such as navigation or entertainment content, directly on the window, reducing the need for drivers to look away from the road to access this information.

In addition, smart windows can improve the energy efficiency of vehicles by reducing the need for air conditioning and heating. By controlling the amount of heat that enters the vehicle, smart windows can reduce the load on the air conditioning system, leading to lower energy consumption and reduced emissions.

Smart windows can be made using various nanomaterials, such as electrochromic materials, which change their color in response to an electrical signal, or photochromic materials, which change their color in response to light.

Overall, the use of smart windows in transportation is a promising area of research and development in nanotechnology, with potential benefits for comfort, safety, and energy efficiency. As more advanced smart windows are developed and applied to vehicles, we can expect to see even more innovative applications in the automotive industry, leading to safer, more comfortable, and more sustainable vehicles.

Improved fuel efficiency

Improved fuel efficiency is one of the most significant potential applications of nanotechnology in transportation. By reducing the weight of vehicles and improving the efficiency of engines and components, nanotechnology can help vehicles consume less fuel and emit fewer pollutants.

Nanomaterials can be used to create lightweight materials, such as carbon nanotubes and graphene, which are stronger and lighter than traditional materials, such as steel and aluminum. By replacing heavy components with lightweight materials, vehicles can achieve significant weight reductions, leading to improved fuel efficiency and reduced emissions.

In addition, nanotechnology can improve the efficiency of engines by reducing friction and wear between moving parts. For example, nanomaterials can be used to create lubricants that reduce friction and wear, leading to improved engine performance and fuel efficiency.

Nanotechnology can also be used to improve the efficiency of energy storage and conversion systems in hybrid and electric vehicles. For example, nanomaterials can be used to improve the performance of batteries and fuel cells, leading to longer driving ranges and shorter charging times.

Overall, the use of nanotechnology to improve fuel efficiency is a promising area of research and development in transportation, with potential benefits for reducing emissions and improving sustainability. As research and development in this area continue, we can expect to see even more innovative applications of nanomaterials in the automotive industry, leading to more efficient and sustainable vehicles.

Improved air and water filtration

Nanotechnology can also be used to improve the filtration of air and water in transportation.

In vehicles, air filtration systems can be improved using nanofiber filters, which can capture smaller particles, such as pollen and pollutants, more efficiently than traditional filters. By improving the efficiency of air filters, vehicles can provide cleaner air for passengers and reduce the risk of respiratory problems.

Similarly, nanotechnology can be used to improve water filtration systems in transportation, such as desalination and wastewater treatment systems. Nanomaterials, such as carbon nanotubes and graphene oxide, can be used to create membranes that can remove contaminants, such as salt and heavy metals, more efficiently than traditional membranes. By improving the efficiency of water filtration systems, transportation can help conserve water resources and reduce the environmental impact of wastewater discharge.

Moreover, nanomaterials can be used to create coatings for surfaces that prevent the growth of bacteria and fungi, improving the cleanliness and hygiene of transportation systems. This is particularly important in public transportation, where the risk of the spread of infectious diseases can be high.

Overall, the use of nanotechnology in improving air and water filtration in transportation is a promising area of research and development, with potential benefits for public health and environmental sustainability. As more advanced nanomaterials are developed and applied to transportation systems, we can expect to see even more innovative applications in the automotive and aviation industries, leading to cleaner and safer transportation.

In Addition, the following points will help you to understand, How Nanotechnology helps to the Automobile sector

- Polymer nanocomposites structural parts, high-power rechargeable battery systems, thermoelectric materials for temperature control, lower rolling resistance tires, high efficiency/low-cost sensors and electronics, thin-film smart solar panels, and fuel additives and improved catalytic converters for cleaner exhaust and longer range are just a few examples of nano-engineered materials in automotive products that have been discussed previously. Metal and cementitious nano-engineering has considerable potential for increasing roadway and transportation infrastructure components’ performance, resilience and lifespan while decreasing their life cycle costs. Self-repairing structures or the capacity to create or transport energy may be incorporated into existing infrastructure materials via new technologies.

- In the future, nanoscale sensors and gadgets may be able to continuously monitor the structural integrity and performance of bridges and tunnels, as well as parking structures and pavements. Using nanoscale sensors, communications devices, and other nanoelectronic innovations, the transportation infrastructure can be enhanced to communicate with vehicle-based systems to assist drivers in maintaining lane position, avoiding accidents, changing travel routes to reduce congestion, and improving drivers’ interfaces with onboard electronics.

- Nanotechnology-enabled lightweight, high-strength materials might have “game-changing” effects on almost every transportation vehicle. The fuel consumption of a commercial jet aircraft may be reduced by up to 15% if its weight were reduced by 20%. Using nanoparticles with double the strength of traditional composites might cut the gross weight of a launch vehicle by as much as 63%, according to preliminary NASA research. To begin with, the amount of energy needed to launch spacecraft into orbit could be significantly reduced, and in the future, single-stage launch vehicles could be developed to achieve orbit. This could lower launch costs, improve mission dependability, and open the door to new concepts for propulsion systems.

- Fuel efficiency is a major goal for automakers, and one of their primary tools is lighter vehicles. As an example, the “Atoms to Engines” team at Ford looked studied the structure of cast aluminium alloys at the atomic level, for example. An in-depth investigation of the structure/property/process relationship of aluminium alloy engine blocks has resulted in decreased weight and improved fuel economy.

- Polymers may also be used to replace mineral glass windows. Key performance requirements have not been met until recently, including scratch resistance and long-term UV resistance. Nanotechnology-based advancements in polycarbonate window development are assisting the industry to overcome these difficulties.

- When compared to standard steel chassis components, weight savings of up to 40% are possible using nanoengineered thermoplastic materials.

- Nanostructured surfaces increase paint adherence and color endurance in paints and surface coatings. In the future, self-cleaning windscreens and automobile body shells will be commonplace. Paints for automobiles that are scratch and abrasion-resistant as well as dirt and UV-resistant are either currently in use or are being developed.

- Nanostructured materials have been used in automotive tires since the early 1990s. For the first time, the automobile industry used carbon black in tires as a color and reinforcement ingredient.

- The rubber combination is the key to tire performance, yet its optimization needs might be contradictory (very complicated chemical and physical interactions between the rubber and the filler material): The tire’s rolling resistance must be kept to a minimum in order to maintain an adequate grip on the road.

- Reinforcing filler accounts for around 30 percent of the tire cover, enabling desired attributes such as grip, abrasion resistance, resistance to early wear and tear, and tear propagation. Soot, silica, and organosilane are three components that considerably enhance the characteristics of natural rubber. A major component of tire performance is the cross-linking of nanoparticles with natural rubber molecules, which now exist in nanoscale form.

- Building an electric car needs to take into account four basic requirements – powerful and safe energy storage to give the car a sufficient driving range; engines and associated electronic components that make the best use of the stored onboard energy; light-weight components to compensate for the (at the moment still) extra weight of the batteries; and all that at a price that can compete with gasoline-powered automobiles.

- Lithium-ion batteries are currently being intensively developed worldwide for use in electric vehicles. The consensus view among researchers is that the battery will be of the lithium-ion type, but which of the lithium-ion chemistries to use is still a major question.

- Nanotechnology holds great promise for improving the performance and lifetimes of Li-ion batteries. It also has the potential to enhance the energy and power density, shorten the recharge time, as well as decrease the size and weight while improving the safety and stability of the batteries. A large number of companies such as Altair Nanotechnologies, mPhase Technologies, A123 Systems, Li-Tec Battery GmbH, NanoEner Technologies, Next Alternative Inc., Nexeon Ltd.,, etc. are actively pursuing the development of nano-enabled batteries while some others are already producing them (see here for an overview of major producers/developers of nano-based batteries and their product range).

- Nanotechnology is also key to improving the fuel cell performance of future generations of hydrogen-powered cars.

- One of the leading fuel cell technologies developed, in particular for transportation applications, is the proton exchange membrane (PEM) fuel cell, also known as polymer electrolyte membrane fuel cells – both resulting in the same acronym PEMFC. These fuel cells are powered by the electrochemical oxidation reaction of hydrogen and by the electroreduction of the oxygen contained in air.

- Although nanotechnology promises cheap bipolar materials using nanocomposites, more efficient non-platinum electrocatalysts, and thermally stable and more durable membranes to become available in the near future, the precious metal platinum still remains the workhorse of PEM fuel cells. One way to minimize platinum usage is to increase catalytic efficiency by nanostructuring the platinum metal; another way of eliminating the use of platinum altogether is by exploring the use of much cheaper non-precious metal catalysts where the nanostructured surfaces match or exceed the catalytic properties of platinum.

- Cars powered by fuel cells will need hydrogen sensors, which will be a key safety component. Leaks will be spotted long before they pose a danger to the public, thanks to their ability to monitor the gas. Nanostructured materials, such as single-walled carbon nanotubes coated with palladium nanoparticles, have previously been used to build thin, flexible hydrogen sensors. Of course, gas guzzlers will be with us for a long time. Applications of nanotechnology will have a significant influence on fuel economy and dangerous exhaust emissions. Due to the friction loss at moving mechanical elements, 10-15 percent of today’s vehicles’ fuel consumption is impacted by engine friction (piston, crank drive, valve drive). Friction and abrasion may be reduced and fuel economy improved by using nanocoatings and nanostructured lubricants on mechanical components.

- Ford is developing a thermally sprayed nanocoating that might replace the heavier cast iron liners in aluminum block engines. Thin wear-resistant coating saves weight and decreases friction while maintaining product longevity and dependability. Piezo fuel injection is utilized in diesel and petrol engines. In direct injection, a pump builds up pressure before shooting fuel via a nozzle into the cylinder’s combustion chamber. Precision affects combustion. The more accurately the injection dosage and duration can be adjusted, the more efficiently fuel will burn. Nanocrystalline piezoelectric materials enhance these. Three-way catalysts purify emissions in gasoline-powered autos. These convert carbon monoxide, nitric oxides, and hydrocarbons to eliminate them from the exhaust gas. Nanotechnologies help convert harmful to non-toxic gases. Catalyst influence varies on surface size. Scaling catalytic material to the nanoscale range enhances specific surfaces. Composition and structure are designed so exhaust gases interact best with the catalytically active coating, accelerating their chemical transformation.

- Nanoparticulate air filters and anti-glare coatings for mirrors and instruments will be the primary focus of car interior applications… Also, how about temperature-controlled automobile seats based on thermoelectrics — materials that turn power into heat or cool immediately?

- More automobile components are controlled electronically, electromechanically, or electromagnetically, driving innovation. Nanostructured actor components might replace direct injection microsystems. Spintronics will change computers. Spintronics utilizes electrons’ spin, which can be controlled by electric and magnetic fields, whereas CMOS relies on electrons’ charge to power devices. Nanoscaled magnetic materials eliminate standby power dissipation in spintronics or electrical devices. Non-volatile electronics may be made with this benefit.

- The developing hybrid automobile industry employs batteries to store energy for electric driving mode and re-uses braking energy. During braking, kinetic energy is transformed into electrical current and stored in accumulators or super or ultracapacitors. Nanotechnologies should have a big influence. Ultralight, flexible batteries, and supercapacitors are already being made from paper.

- Some automobiles feature micro-structured solar cell sunroof options. Using nanostructured, flexible plastic solar cells with a thickness of less than 1 micron, solar energy harvesting thin films may cover bigger automobile exterior regions. Today’s autos have a 1 percent electrical-to-optical efficiency for illumination. Diffractive micro-optics, new light sources, and power supply integration will enhance this.