Flywheel-energy-storage

Introduction

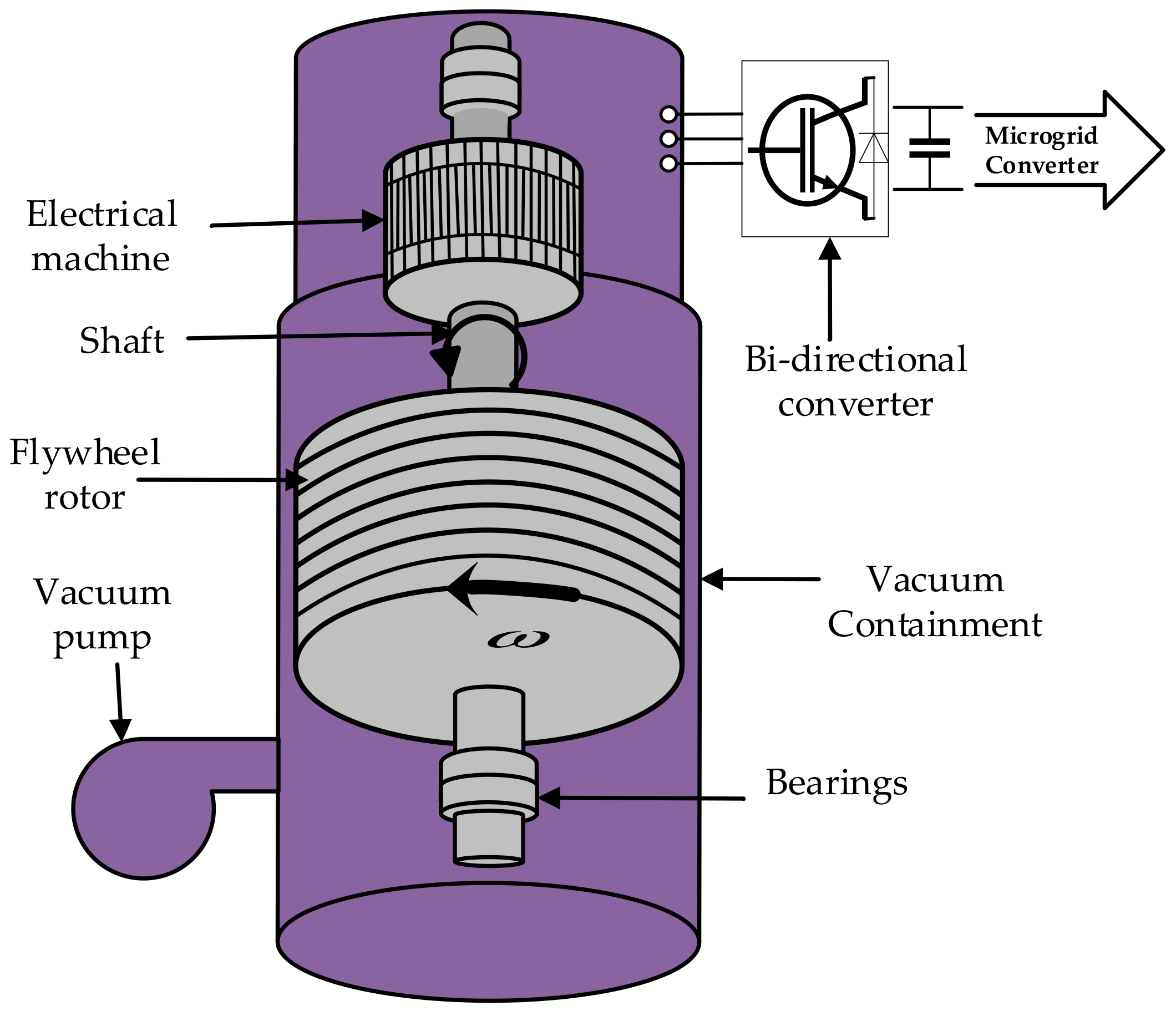

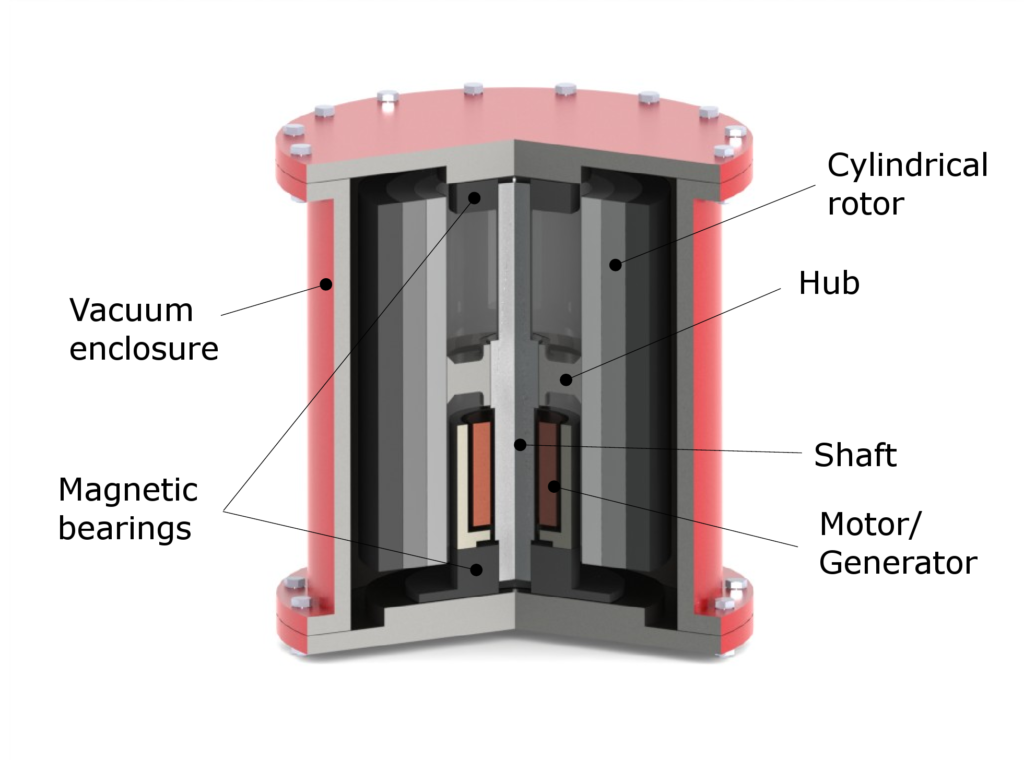

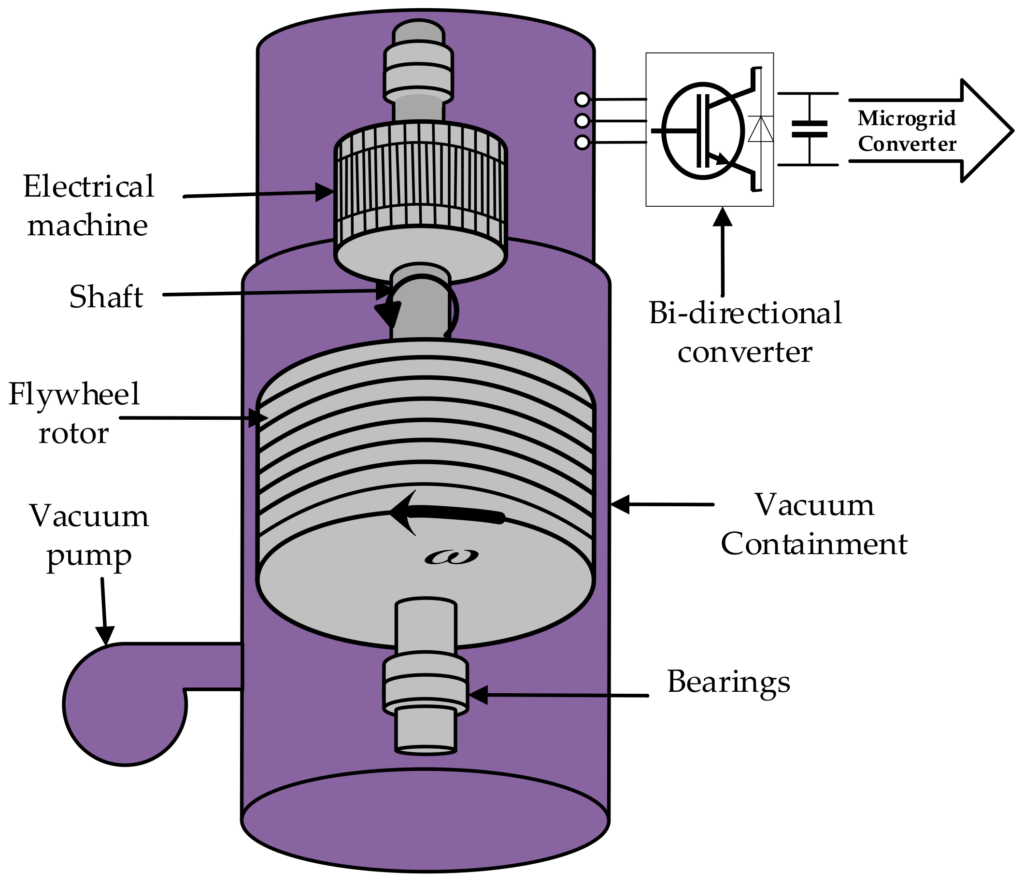

Flywheel-energy-storage is a method of storing energy in the form of rotational kinetic energy, which is achieved by using a spinning rotor that is connected to a generator. The rotor is enclosed within a vacuum chamber and suspended on magnetic bearings, which helps minimize friction and increase the efficiency of the system. When energy is needed, the rotor’s rotational energy is converted back into electrical energy through the generator.

The concept of flywheel energy storage has been around for a long time and has been used in various applications such as transportation, industry, and power generation. However, recent advancements in materials, manufacturing, and control systems have made flywheel energy storage more practical and cost-effective.

Flywheel energy storage systems can be divided into two main categories based on the speed of the rotor: high-speed flywheels and low-speed flywheels. High-speed flywheels typically operate at speeds between 20,000 and 60,000 revolutions per minute (RPM) and can store energy for a few seconds to a few minutes. Low-speed flywheels, on the other hand, operate at speeds between 1,000 and 10,000 RPM and can store energy for several hours.

High-speed flywheel energy storage systems are commonly used for short-term energy storage applications such as providing backup power to critical loads, stabilizing grid frequency, and smoothing out fluctuations in renewable energy sources such as wind and solar. Low-speed flywheel energy storage systems, on the other hand, are better suited for longer-term energy storage applications such as off-grid power systems, remote locations, and microgrids.

The main advantages of flywheel energy storage systems include high power density, fast response time, high efficiency, and long cycle life. The high power density means that flywheels can store a large amount of energy in a relatively small space, making them ideal for applications where space is limited. The fast response time means that flywheels can respond quickly to changes in demand or supply, making them useful for grid stabilization and renewable energy integration. The high efficiency means that flywheels can convert energy back and forth with very little loss, making them cost-effective in the long run. Finally, the long cycle life means that flywheels can last for many years without significant degradation, making them a reliable and low-maintenance energy storage solution.

There are also some challenges associated with flywheel energy storage systems, such as the high cost of the materials used to manufacture the rotor, the need for a vacuum chamber to minimize air resistance, and the risk of catastrophic failure if the rotor is not properly contained. However, these challenges are being addressed through ongoing research and development, and the cost of flywheel energy storage systems is expected to decrease over time as the technology becomes more widespread.

In conclusion, flywheel energy storage is a promising technology that has the potential to play an important role in the transition to a more sustainable and reliable energy system. While there are still some challenges to be addressed, the advantages of flywheel energy storage systems make them a viable option for a wide range of energy storage applications.

The fundamental mechanism of flywheel-energy-storage

The fundamental mechanism of flywheel energy storage is the conversion of electrical energy into rotational kinetic energy stored in a spinning rotor, and the subsequent conversion of the stored kinetic energy back into electrical energy when needed.

Sources: Clean Technol. 2021, 3(2), 351-376

In a flywheel energy storage system, the rotor is connected to a motor/generator, which can either accelerate the rotor to store energy or convert the stored energy into electrical power. When electrical energy is supplied to the motor, it spins the rotor, which stores energy in the form of rotational kinetic energy. The energy is stored by increasing the speed of the rotor, and the amount of energy stored is proportional to the square of the rotational speed and the moment of inertia of the rotor.

The rotor is designed to be as light as possible while still having a high moment of inertia to maximize the amount of energy that can be stored. The rotor is also housed in a vacuum chamber to reduce air resistance and minimize energy loss due to friction. The rotor is suspended in the vacuum chamber by magnetic bearings, which are used to levitate the rotor and reduce friction. The magnetic bearings also allow the rotor to spin at high speeds without touching any solid surfaces, which helps minimize wear and tear and increases the efficiency of the system.

When energy is needed, the stored kinetic energy in the spinning rotor is converted back into electrical energy through the generator. The generator is connected to an electrical load, such as a motor or a grid, and as the rotor slows down, the rotational energy is converted back into electrical energy. The electrical energy can then be used to power devices or fed into the grid as needed.

The rate at which energy can be stored or discharged from a flywheel energy storage system depends on the design of the system, including the mass and shape of the rotor, the speed at which it spins, and the efficiency of the motor and generator. Additionally, the energy storage capacity of a flywheel energy storage system is limited by the maximum rotational speed of the rotor and the maximum allowable stresses on the rotor materials.

Overall, the fundamental mechanism of flywheel energy storage is a simple and effective way to store and release energy quickly and efficiently. The use of magnetic bearings, vacuum chambers, and high-speed motors and generators has made flywheel energy storage an increasingly practical and cost-effective solution for short-term energy storage applications

Benefits and Drawbacks of Flywheel energy storage:

Benefits of Flywheel Energy Storage:

- High Power Density: Flywheel energy storage systems have a high power density, which means they can store a large amount of energy in a small space, making them suitable for applications where space is limited.

- Fast Response Time: Flywheel energy storage systems have a fast response time, meaning they can respond quickly to changes in demand or supply. This makes them useful for grid stabilization and renewable energy integration.

- High Efficiency: Flywheel energy storage systems have high efficiency, which means they can convert energy back and forth with very little loss, making them cost-effective in the long run.

- Long Cycle Life: Flywheel energy storage systems have a long cycle life, meaning they can last for many years without significant degradation, making them a reliable and low-maintenance energy storage solution.

- Low Maintenance: Flywheel energy storage systems are low maintenance compared to other types of energy storage systems. They do not require the use of chemicals, have no risk of leaks or fires, and have a longer lifespan.

Drawbacks of Flywheel Energy Storage:

- High Cost: Flywheel energy storage systems can be expensive to manufacture and install. The cost is mainly due to the use of high-quality materials needed to construct the rotor, vacuum chamber, and magnetic bearings.

- Limited Energy Storage Capacity: Flywheel energy storage systems have limited energy storage capacity, and they are best suited for short-term energy storage applications.

- Risk of Mechanical Failure: The high rotational speeds of the flywheel rotor mean that there is a risk of mechanical failure if the rotor is not properly contained. A catastrophic failure could lead to significant damage and safety risks.

- Energy Loss due to Friction: Despite the use of magnetic bearings, some energy is lost due to friction, which reduces the efficiency of the system.

- Sensitivity to Temperature: Flywheel energy storage systems are sensitive to temperature, and they must be designed to operate within a specific temperature range to prevent thermal expansion or contraction, which could lead to mechanical failure.

In conclusion, flywheel energy storage systems have many benefits, including high power density, fast response time, high efficiency, long cycle life, and low maintenance. However, they also have some drawbacks, such as high cost, limited energy storage capacity, the risk of mechanical failure, energy loss due to friction, and temperature sensitivity. These limitations are being addressed through ongoing research and development, and the technology is expected to become more cost-effective and practical in the future.

Future Prospective Flywheel Energy Storage:

Flywheel energy storage has the potential to play a significant role in the future of energy storage, especially as renewable energy sources such as wind and solar become more prevalent in the energy mix. Here are some prospects for flywheel energy storage:

- Increased Energy Density: Advances in materials science and engineering could lead to flywheel energy storage systems with higher energy density. Higher energy density would allow for more energy to be stored in a smaller space, making flywheel energy storage more practical for a wider range of applications.

- Integration with Renewable Energy: Flywheel energy storage is well-suited for integration with renewable energy sources such as wind and solar. As renewable energy sources become more prevalent, flywheel energy storage could play an important role in smoothing out fluctuations in power supply and demand, thereby enhancing grid stability.

- Hybrid Energy Storage Systems: Flywheel energy storage could be combined with other energy storage technologies such as batteries or pumped hydro to create hybrid energy storage systems. Hybrid systems could provide the benefits of both technologies, such as high power density from flywheels and high energy density from batteries or pumped hydro.

- Transportation Applications: Flywheel energy storage could be used in transportation applications, such as electric buses or trains, to store energy during regenerative braking and release it during acceleration. This would increase the energy efficiency of these transportation systems and reduce their carbon footprint.

- Space Applications: Flywheel energy storage has potential applications in space exploration and satellite missions, where energy storage is crucial. Flywheel energy storage is a low-maintenance and reliable technology that can withstand the harsh conditions of space, making it an attractive option for these applications.

Overall, the future of flywheel energy storage looks promising. Ongoing research and development are expected to lead to advancements in technology, making it more efficient, cost-effective, and practical for a wider range of applications. As renewable energy becomes more prevalent, flywheel energy storage is expected to play an increasingly important role in enhancing grid stability and enabling a transition to a cleaner energy future.

List of largest flywheel energy storage systems around the world

Here are some of the largest flywheel energy storage systems (FESS) around the world:

- Beacon Power 20 MW Smart Energy Matrix in the US

- Schwungrad Energie 10 MW in Germany

- NRStor Minto 2 MW in Canada

- Stornetic 2 MW in Germany

- Amber Kinetics 1 MW in the US

- Temporal Power 500 kW in Canada

- Ricardo 100 kW in the UK

- University of Sheffield 100 kW in the UK

- Chugoku Electric Power Company 20 kW in Japan

- Tokyo Institute of Technology 2 kW in Japan

Socioeconomic impact of flywheel energy storage systems

Flywheel energy storage systems (FESS) are an emerging technology that stores energy in the form of rotational kinetic energy. FESS systems have been shown to have numerous advantages over traditional battery storage systems, including higher efficiency, longer lifespan, and higher power density. As a result, FESS systems have attracted increasing attention from researchers, industry, and policymakers. This paper aims to examine the socioeconomic impact of flywheel energy storage systems.

One of the primary advantages of FESS systems is their ability to store energy more efficiently than traditional battery storage systems. FESS systems have a round-trip efficiency of up to 90%, which is significantly higher than traditional battery storage systems, which typically have a round-trip efficiency of around 70%. This higher efficiency means that FESS systems can store more energy while wasting less energy in the process, leading to lower overall energy costs.

Another advantage of FESS systems is their long lifespan. Traditional battery storage systems have a limited number of charge and discharge cycles before they need to be replaced, typically around 5,000 cycles. In contrast, FESS systems can last up to 100,000 cycles before needing to be replaced, resulting in lower maintenance costs and longer lifetimes. This increased lifespan also means that FESS systems have a lower environmental impact than traditional battery storage systems, as fewer materials are required for manufacturing and fewer systems need to be disposed of.

Is flywheel energy storage expensive

Flywheel energy storage systems are a type of mechanical energy storage system that has been gaining attention in recent years due to their potential for use in a variety of applications. These systems work by storing kinetic energy in the rotation of a flywheel, which can then be converted back to electrical energy when needed. While flywheel energy storage systems offer several benefits, one of the primary concerns is their cost.

When compared to other forms of energy storage, such as batteries or pumped hydro, flywheel energy storage systems can be relatively expensive. This is due in part to the fact that they require high-precision manufacturing, which can be costly. Additionally, flywheel energy storage systems require specialized components, such as magnetic bearings, which can add to the overall cost.

Another factor that can contribute to the cost of flywheel energy storage systems is their efficiency. While flywheel systems are generally considered to be highly efficient, with efficiencies ranging from 70% to 95%, this efficiency can come at a higher cost. To achieve high efficiencies, flywheel systems require high-quality components and precise control systems, which can add to the cost.

However, it is important to note that the cost of flywheel energy storage systems has been declining in recent years, as advances in technology have led to improvements in efficiency and reduced manufacturing costs. Additionally, the potential applications for flywheel energy storage systems, particularly in the areas of grid stabilization and renewable energy integration, may make them an attractive option despite their higher upfront cost.

Furthermore, it is important to consider the overall cost-benefit analysis of flywheel energy storage systems. While they may be more expensive initially, they offer many advantages over other forms of energy storage, such as high power density, fast response times, and long lifetimes with little maintenance. These advantages may ultimately lead to lower overall costs over the lifespan of the system, particularly in applications where high reliability and fast response times are critical.

In conclusion, while flywheel energy storage systems may be relatively expensive when compared to other forms of energy storage, their unique advantages, such as high power density and fast response times, may make them an attractive option for certain applications. As technology continues to advance and manufacturing costs continue to decline, the cost of flywheel energy storage systems will likely become more competitive with other forms of energy storage in the future.

List of top 10 books on Flywheel-energy-storage

- “Flywheel Energy Storage Systems” by Brian P. Norton

- “Flywheel Energy Storage: An Alternative Approach to Battery Storage” by P.M. Anderson

- “Flywheel Energy Storage for Power Systems” by Xinye Zhang and Wenping Cao

- “The Flywheel and Its Potential for Energy Storage” by Paul Breeze

- “Flywheels: Energy Storage for the 21st Century” by E.A. Lomonova and A.J. Moses

- “Flywheel Energy Storage: Current State-of-the-Art and Future Directions” by Lei Shu and Zhigang Yang

- “High-Speed Flywheels: Energy Storage and Conversion” by R.P. Kotzeva and T.A. Lipo

- “Flywheel Energy Storage Technology for Power Applications: State of the Art and Future Prospects” by Sohrab Mirsaeidi and Gholamreza Farshidi

- “Flywheel Energy Storage: An Overview” by F. Carli, M. Bortolotto, and M. Morandin

- “Flywheel Energy Storage: Novel Solutions for Future Energy Storage Systems” by Marcin Czekała and Piotr Kędziora.